Challenge

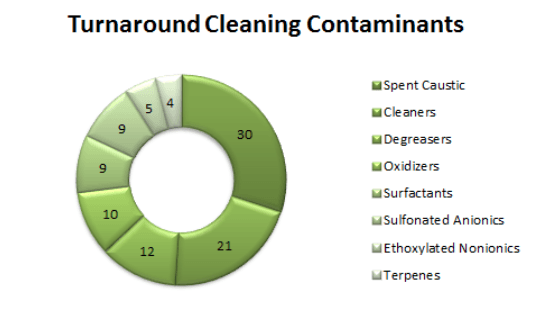

A refinery needed a contractor to “…handle our vapor control and compliance needs during this major turnaround. We need you to keep us in compliance and provide accurate and complete records upon completion.” We can do that – it is what we do. The challenge was to handle the vapor control for 250 frac tanks and the blow downs from the towers, columns, and vapors from the vacuum trucks.

Solution

The engineers at Envent developed a plan that involved staffing the turnaround with engineers, providing vapor scrubbers that fit the service, and using thermal oxidizers engineered and sized for the task. We had 17 scrubbers, both passive and recirculating, and 3 thermal oxidizers from 5 MMBTU to 40 MMBTU being manned and operated at one time.

Benefit

Our engineers and technicians executed the entire 60 day turnaround incident free and the customer was extremely satisfied. The success of the turnaround was the result of Envent’s experience and highly specialized and trained personnel.

Envent’s 24 hour manned operation ensured the turnaround vapor control activities were done correctly and safely, and we remained in compliance.