Envent hosts customers after ILTA Conference at the 8th Wonder Brew Pub.

1 – Dennis Herfort – Enterprise Products

2 – Lara O’Brien – Enterprise Products

3 – Andy Maas – Enterprise Products

4 – JD Jaeger – Envent

5 – Jeremy Osterberger – BIC

Envent hosts customers after ILTA Conference at the 8th Wonder Brew Pub.

1 – Dennis Herfort – Enterprise Products

2 – Lara O’Brien – Enterprise Products

3 – Andy Maas – Enterprise Products

4 – JD Jaeger – Envent

5 – Jeremy Osterberger – BIC

Call Envent now to see how Colorado Air Quality Control Commission February 23, 2014, Air Quality Control Commission Regulation #3 can be managed at your facility!

Come See Us at Booth # 1415

2014 TCEQ Environmental Trade Fair & Conference

May 6-7, 2014- Austin, TX

Continue reading “2014 TCEQ Environmental Trade Fair & Conference”

At Envent, we don’t just “do our job”. We make sure we exceed our clients expectations. In our industry that is highly technical and demanding, the service we provide truly makes the difference. Over the years we have been grateful for praise and thanks from many of our clients. Here’s another testimonial from Pat of Petro-Diamond Terminal Co. :

“Just wanted to say thank you for your excellent service in providing vapor control for our needs, with such short notice. Juan and the rest of your technicians were knowledgeable, friendly and very professional. Their help is greatly appreciated.”

Cheers!

Donation “Fight On!” will benefit the Semper Fi Fund which provides financial assistance to wounded soldiers and their families.

We see this move as an opportunity to give back to those who gave so much! Envent doesn’t only help clean the environment; we are also active in promoting activities for a worthy cause.

Introducing our newest innovation: The Envent Mobile Vapor Bladder System – VBS

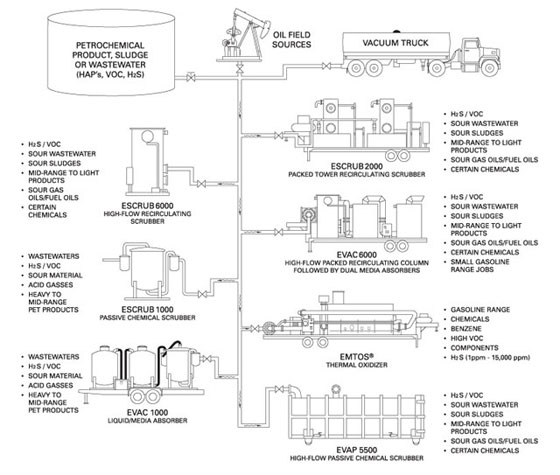

The Environmental Protection Agency (EPA) estimates that the upstream and midstream segments of the oil and gas industry account for nearly 40 percent of volatile organic compound (VOC) emissions in the United States. As a result, the agency has proposed strict regulations on facilities that use storage vessels.

Air pollution is a serious issue for oil and gas industry professionals, so the monitoring of emissions regulations is a priority and a constant concern.

Due to a lack of regulations regarding storage vessels, the EPA proposed new standards, commonly referred to as 40 CFR 60, Subpart OOOO (Quad O), which took effect on Oct. 15, 2012, and have a one-year compliance phase.

Facilities with a Potential to Emit (PTE) of greater than six tons of VOCs yearly must install one of three approved control devices: a standard flare, an enclosed combustor, or a vapor recovery device. The standard flare must meet both 40 CFR 60.18 and Method 22A (producing no smoke from the device). The New Source Performance Standard (NSPS) in 40 CFR Part 60, Subpart Quad O, requires all combustion control devices to reduce emissions to less than six tons yearly with a 95 percent destruction and removal efficiency (DRE).

The standard also includes testing requirements. Facilities must have devices tested and retested by a third party at regular intervals, which are commonly interpreted as 180 days upon installation and startup, and within five-year intervals thereafter, or, the manufacturer provides third-party testing. Continue reading “Overview of EPA’s Quad O Standard”

This all stainless steel mobile unit combines a proprietary recirculating liquid scrubber and packed column with a carbon polish. It removes emissions of H2S, Ammonia and Organics from vapor streams in a single fully transportable system.

This unit can be mobilized in just minutes our hours. Our engineers will quickly work with you to determine the best liquid solution that can be used in this system. Call Envent at 888-997-9465 or email us at solutions@envent.net.

The Coast Guard is revising existing safety regulations for facility and vessel vapor control systems (VCSs) to promote maritime safety and marine environmental protection. The revisions promote safe VCS operation in an expanded range of activities now subject to current Federal and State environmental requirements, reflect industry advances in VCS technology, and codify the standards for the design and operation of a VCS at tank barge cleaning facilities. They increase operational safety by regulating the design, installation, and use of VCSs, but they do not require anyone to install or use VCSs.

[wpfilebase tag=file id=267 tpl=’dload_button_nocount’ /]

Envent attends the CTAC Committee meeting in Washington DC on May 7 & 8. The end result of this meeting was the attached Policy Letter from the United States Coast Guard on the Safe Operation of Mobile Vapor Control Systems. The USCG provided the attached Policy Letter clarifying that CFR 154 safety equipment, shutdowns and controls requirements will not be replaced by a man standing nearby ready to push the mushroom as some competitors seem to have been hawking. Customers now have the piece of mind and clear guidance that the USCG wants things done safely. Envent will provide that safety system in our prepacked Envent EMECS and Envent Dock Safety Unit (DSU).

[wpfilebase tag=file id=268 tpl=’dload_button_nocount’ /]

Long Beach, CA – March 13, 2013 – On March 12th, Envent receives Chevron Refining’s Highest Safety Award – The Gold Star Safety Excellence Award for 2012. The next day, Envent is awarded the 2012 Outstanding Crew Award & The much sought after HES Leadership Award from Chevron Pipe Line for 2012.

According to Envent HES Director Brian Miller, “this was an exciting week for me, being handed the Gold Star Safety Excellence Award from Chevron El Segundo on Tuesday by the El Segundo Plant Manager, then driving up to the Western HQ for Chevron Pipe Line the next day to receive the 2012 Outstanding Crew Award from the CPL Western Unit Business Manager”. What a great week for Envent and nicely done! On top of that Envent was awarded the Contractor Health, Environment & Safety Leadership Commitment Award!

The 2012 Chevron Refining Award was given to Envent after another stellar safety and operational year and it is always nice to be recognized for our efforts. Envent was selected from 350 CPL contractors. Envent crews underwent 12 separate customer HES audits during multiple jobs that were part of an emergency response. In each audit, Envent employees nailed it. What a great achievement and for Envent, the credit lies with the employees who buy in to our commitment to safety and compliance.

This is the 4th year in a row that Envent Corporation has received Health, Safety & Environmental Excellence Awards from Chevron!

The 3 Most Common Areas of Concern your Provider Should Address before You Sign on the Dotted Line

We at Envent have been in the business of mobile vapor and water treatment for over 20 years. We are fully aware that degassing jobs at refineries and petrochemical plants, two of the most technically sophisticated places on the planet, require a zero tolerance policy for mistakes. It’s the way it should be, and there is no substitute for just plain doing things “the right way.” Degassing and vapor control is too important to be left in the hands of an inexperienced operator, so we thought we would let you in on the three most common concerns we address from our customers so you can ensure that you, too, are in more than capable hands when you decide on who to hire for the job.

Continue reading “Is your Petrochemical Plant in Need of a Degassing Operator?”