Achieving Net-Zero Methane Emissions: Envent Corporation’s Advanced Pipeline Evacuation & Cross Compression Solutions

In today’s energy sector, minimizing environmental impact while maintaining operational efficiency is paramount. Envent Corporation stands at the forefront of this mission, offering state-of-the-art Pipeline Evacuation and Natural Gas Cross Compression services designed to meet the industry’s evolving needs.

Innovative Solutions for Pipeline Maintenance

Envent’s mobile natural gas compression services—also known as cross compression or recompression—are engineered to safely remove methane from pipeline sections requiring maintenance, servicing, or hydrostatic testing. Traditionally, operators would vent or flare methane, leading to environmental concerns and product loss. Envent’s approach captures and reintroduces this valuable resource back into the active pipeline, aligning with best practices and regulatory standards.

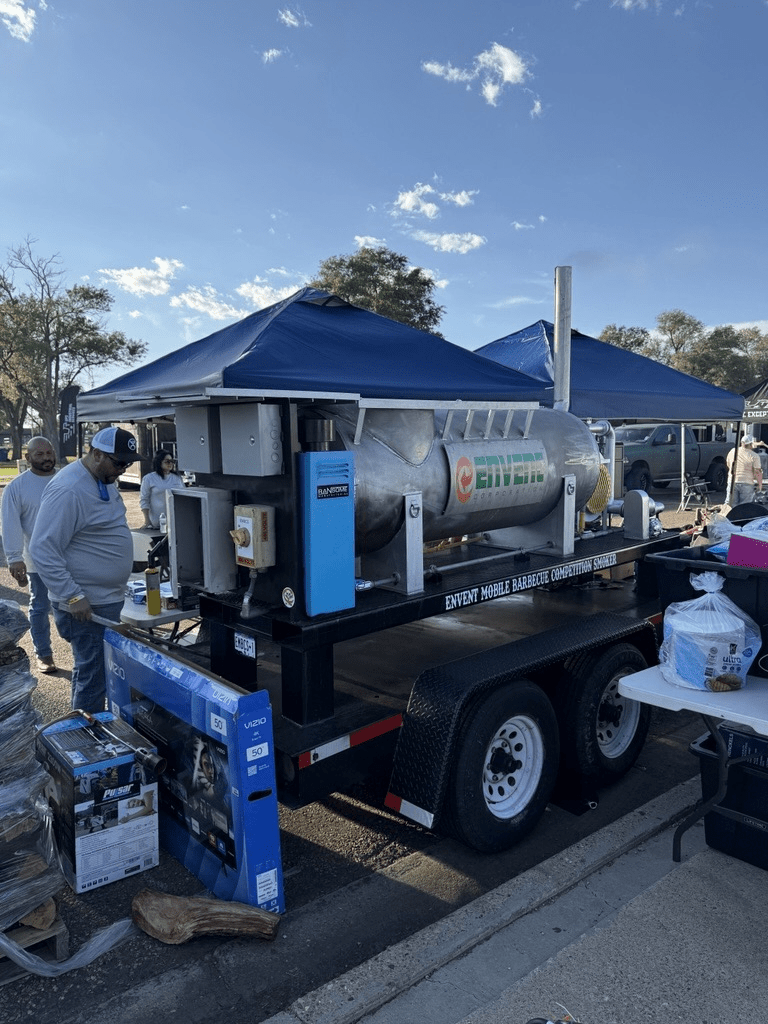

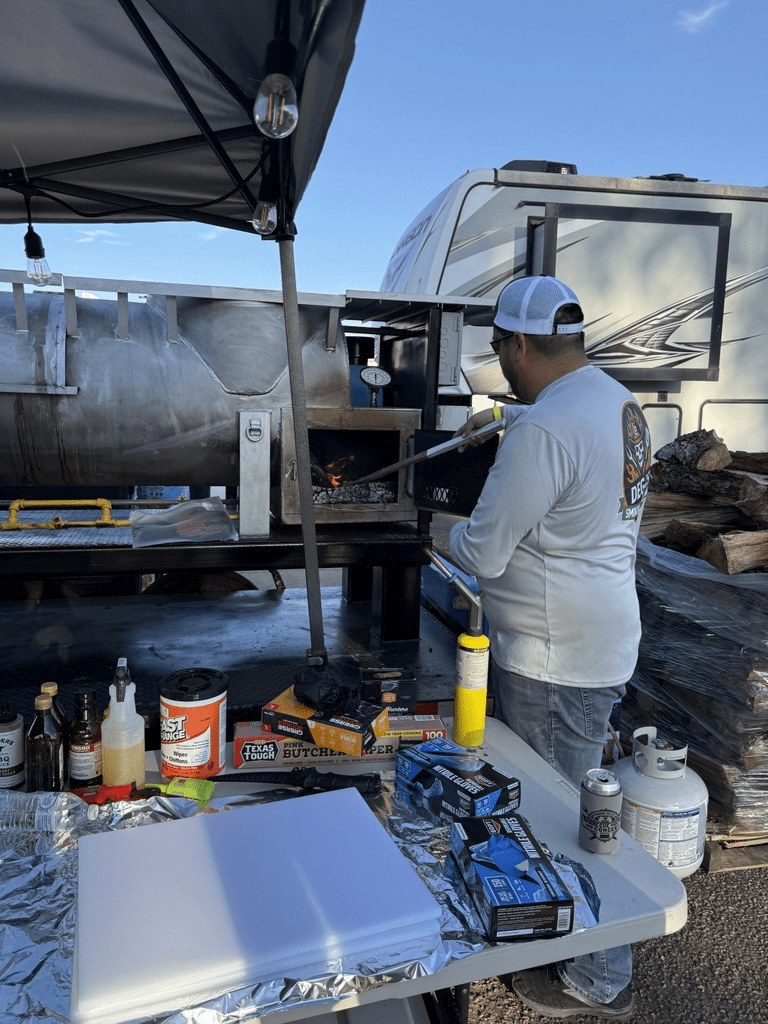

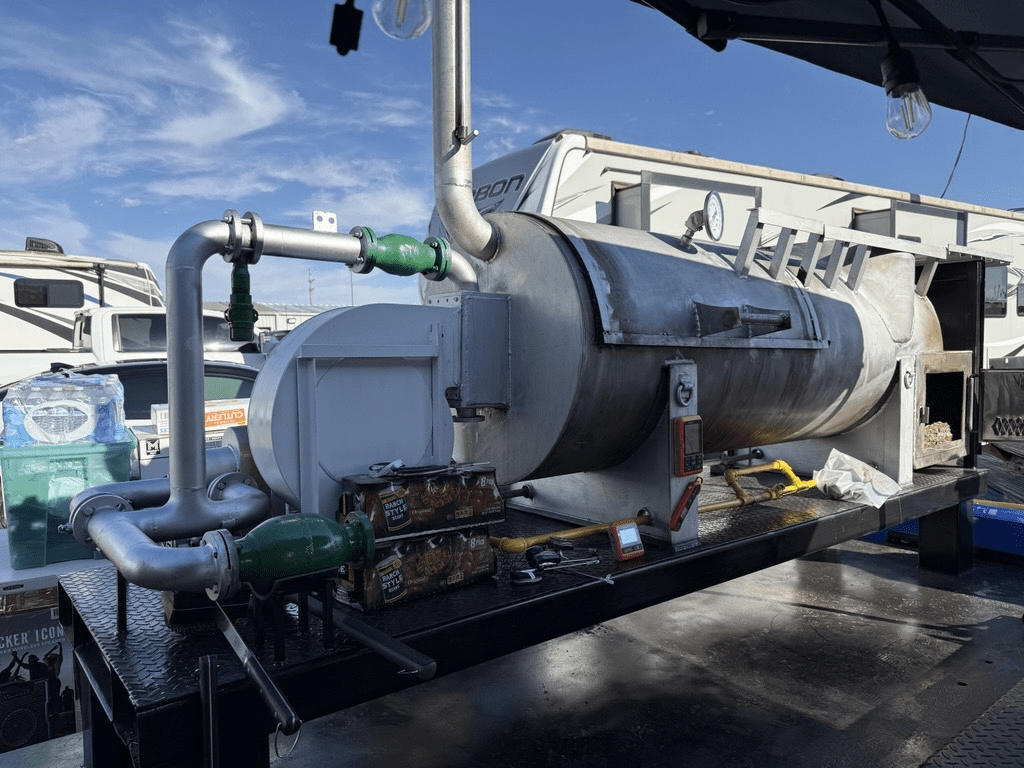

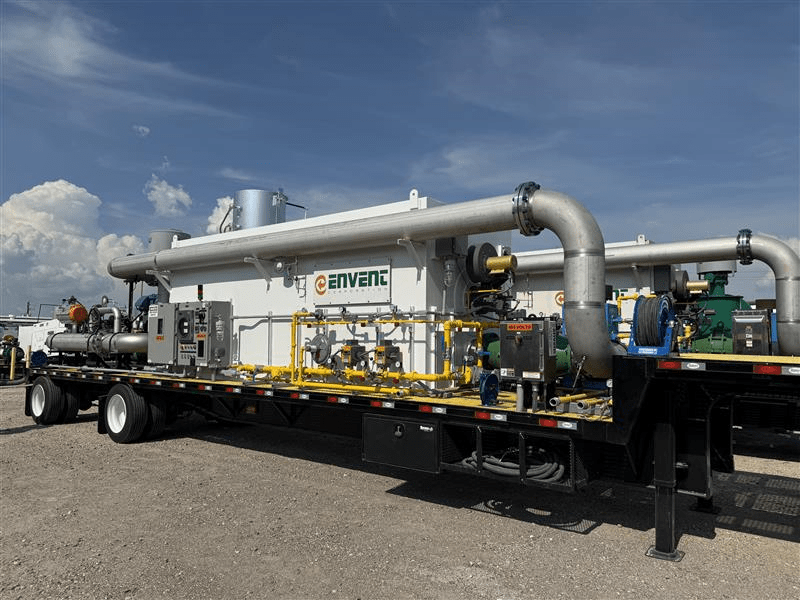

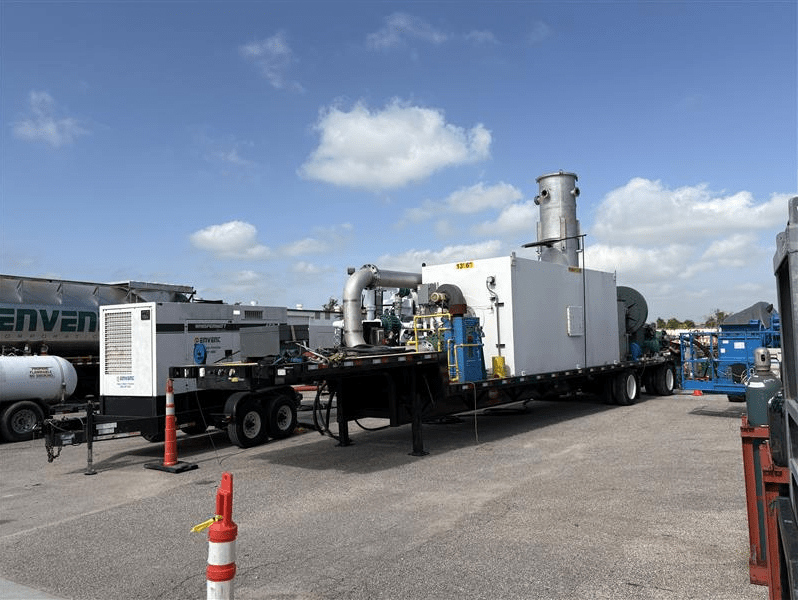

State-of-the-Art Mobile Compression Units

At the heart of Envent’s service is a fleet of advanced mobile compressors, featuring Caterpillar engines, Ariel compressors, and proprietary safety systems. These units are designed to reduce pipeline pressure from 1400 PSIG to below 5 PSIG within hours, facilitating safe and efficient maintenance operations. All equipment complies with ASME code standards and is operated by OQ-certified professionals, ensuring top-tier performance and safety.

Compliance with PHMSA Mega Rule

In response to the Pipeline and Hazardous Materials Safety Administration’s (PHMSA) Mega Rule, which mandates enhanced pipeline safety measures, Envent’s services offer a compliant solution. By employing cross compression techniques, Envent helps operators meet regulatory requirements while achieving net-zero methane emissions—a significant step toward environmental stewardship.

Rapid Deployment Across North America

With strategically located offices throughout North America, Envent ensures rapid mobilization to job sites, providing timely support for both planned and emergency maintenance activities. This nationwide reach underscores Envent’s commitment to responsive and reliable service delivery.

A Legacy of Environmental Excellence

Since 1992, Envent Corporation has been a trusted partner in the oil and gas industry, delivering innovative solutions that prioritize safety, compliance, and environmental responsibility. Their comprehensive suite of services—including degassing, vapor control, and water treatment—reflects a deep understanding of industry challenges and a dedication to sustainable operations.

For more information about Envent’s Pipeline Evacuation and Natural Gas Cross Compression services: Envent Corporation Services.